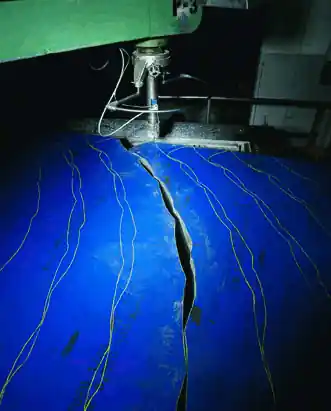

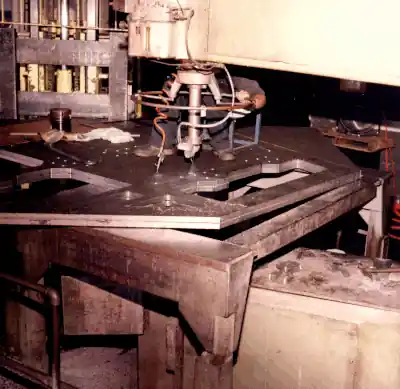

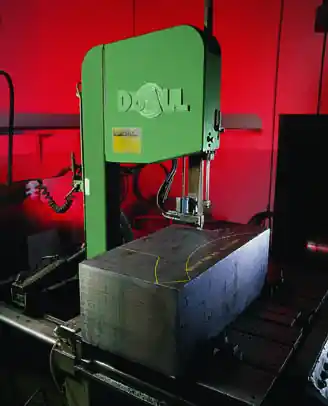

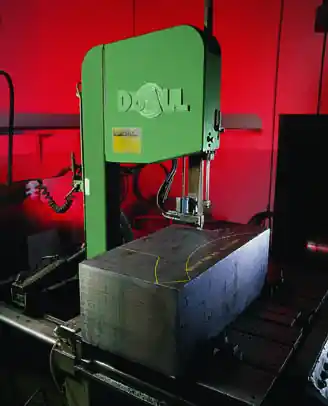

THE LARGEST PROVIDER OF VERTICAL SAWING

Since 1956 ISO Certified Metal Cutting Service has been providing top quality notch and shape sawing services from our 32,000 square foot facility in the City of Industry, CA. Get industry-leading equipment capabilities and material industry experience that gets you the most of your material usage – with an emphasis on quality, high volume and fast turn around times.

Materials We Notch & Shape

Titanium

Stainless Steel

Aircraft Alloys

Aluminum

Tool Steel

Mild Steel

Superalloys

Plastics

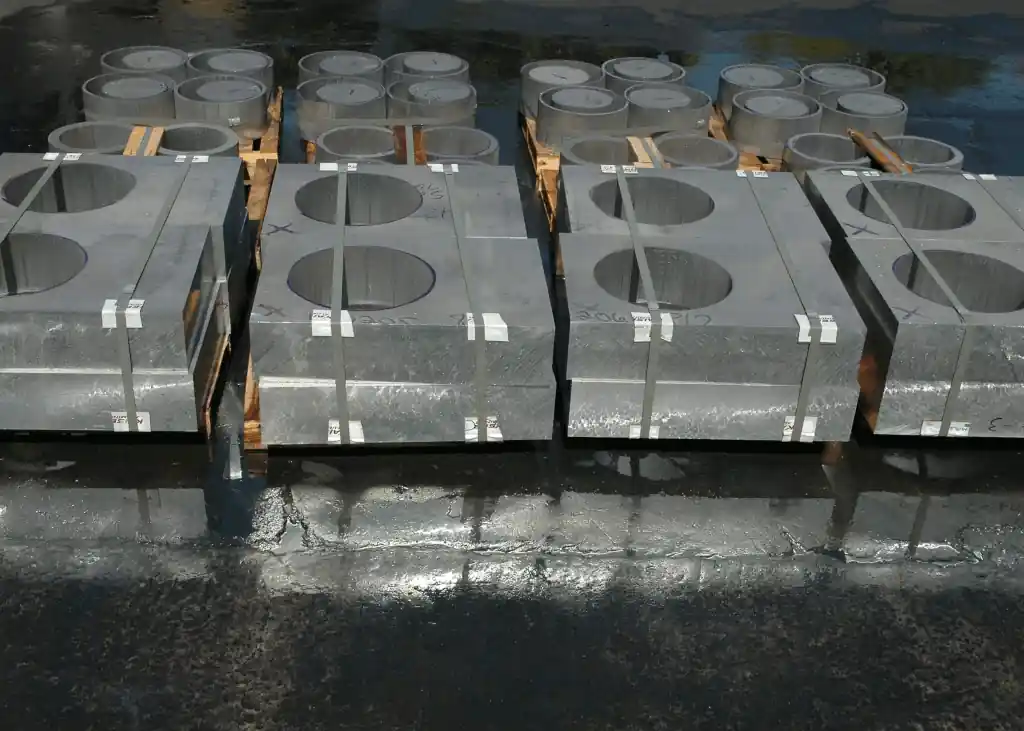

Common Notch & Shape Sawing Jobs

Carbide Plate Sawing :

"Hot Rod " Axles

Nuclear Submarine

Stainless Bellows

Hydraulic Valve Shape Cutting

Aircraft Landing Gears

Computer Chip Manufacturer Chambers

Small Mold Pocket Cutting

Aluminum Plate Shapes

Bandsaw Plate Sawing :

No items found.