GET MORE OF THE CUTS YOU NEED

At MCS, we redefine plate sawing, offering an unparalleled experience like never before. With the largest volume capabilities in the United States and unmatched size capacities in thickness, width, and length, we stand at the forefront of the industry.

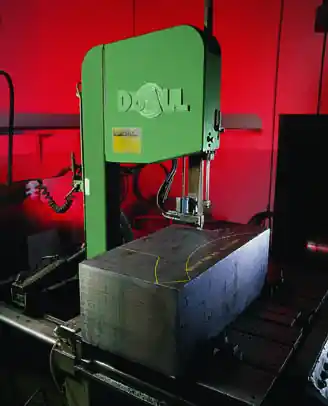

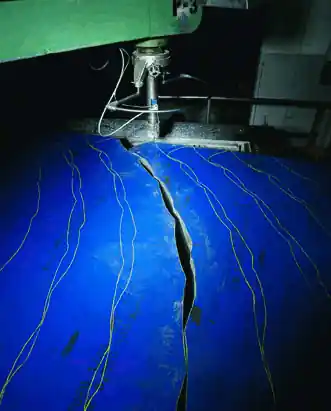

Our expertise in bandsaw plate saws spans an impressive 67 years, during which we've accumulated unrivaled knowledge in cutting the largest and most unique orders. Our size capacities are truly unique in the United States, complemented by high-volume capabilities found nowhere else.

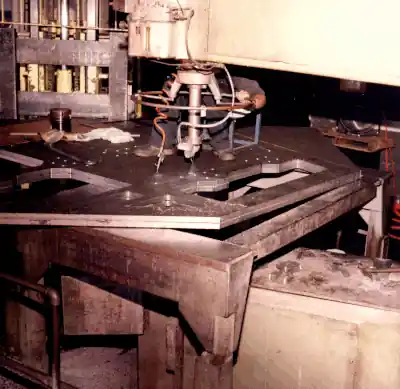

For our carbide plate saws, we employ cutting-edge technology, featuring high-speed circular blades that guarantee precision when cutting non-ferrous plates. While carbide saws excel at cutting materials like aluminum and other non-ferrous alloys in plate or sheet form, our expertise extends to crafting notches in forgings and extrusions. Experience the pinnacle of plate sawing precision with MCS.

Materials We Plate Saw

Common Plate Sawing Jobs